Troubleshooting

NOTE:

Slow cutting and short blade life are common problems with diamond blades.

It is very important to understand that the segment of the blade is designed to wear at a certain rate. That is one of the important factors that makes one blade different from another.

Slow Cutting Speed

Cause: Usually occurs when a blade is used to cut a material that is too hard for the segment. The hard material wears the exposed diamonds, but not the metal portion of the segment. The segment wears too slowly, no new diamonds are exposed, and you see slow cutting speed.

Solution: Cut a soft, abrasive material until diamonds are well exposed. Try Asphalt, block, sandstone, or dried mortar. Choose the proper blade for the application.

Potential: If this problem is allowed to continue, heat builds up and the blade begins to bounce leading to segment loss, core cracks and a very unsafe condition.

Short Blade Life

Cause: Usually occurs when a blade is used to cut a material that is too soft and abrasive for the segment.

The abrasive material wears the metal of the segment too fast, and you see short blade life.

Solution: Specify the correct blade, choose a more wear resistant bond. Check water flow. Make sure blade is rated for the equipment used. Check saw is in good condition.

Potential: If blade specification is not changed the problem will reoccur. Customer will not get the full life and efficiency of the diamond tool.

Core or Segment Cracks

Cause: Blade wobbling & vibration due to improper rpm applied on the blade. Blade runs out of round due to machine condition. Blade is too soft or too hard for material. Saw is in need of repair. Blade mounted improperly. Twisting while cutting or attempting to cut curves.

Solution: Select a properly bonded blade for the material. Check all bearings, belts, shaft

and flanges. Check direction of blade travel. Follow guidelines for proper blade

operation and cooling procedures.

Potential: If this problem is allowed to continue it will result in segment loss and possible

core destruction. This is an extremely dangerous situation. Do not continue to use the blade.

Wobbling/Warped Blade

Cause: Lack of cooling water while cutting. Clogged water supply. Blade is out of tension…the steel core is not straight. Wrong size collars or mounted incorrectly.

Blade allowed to overheat (bluish black marks). Blade run at improper RPM.

Solution: Make sure enough cooling water is supplied on the steel core and outer rim of

collars. Use the correct sized blade collars. Check flanges are smooth and tight fitting. Follow guidelines for proper blade operation and cooling procedures. Check RPM rating for blade and saw.

Potential: If this problem is allowed to continue, heat builds up and the blade begins

to bounce leading to segment loss, core cracks and a very unsafe condition.

Produces poor quality cuts.

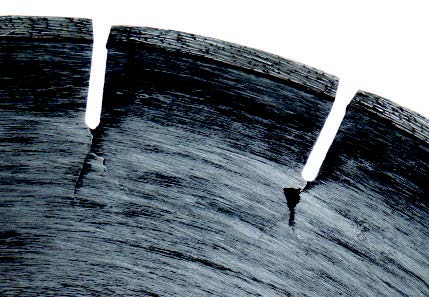

Undercutting

Cause: Steel core is worn faster than segments by abrasive material being cut.

Solution: Specify a blade with wear-retardant design. Increase water flow to flush cut.

Potential: If this problem is allowed to continue, the core will wear out from

under the segment and allow the segments to separate.